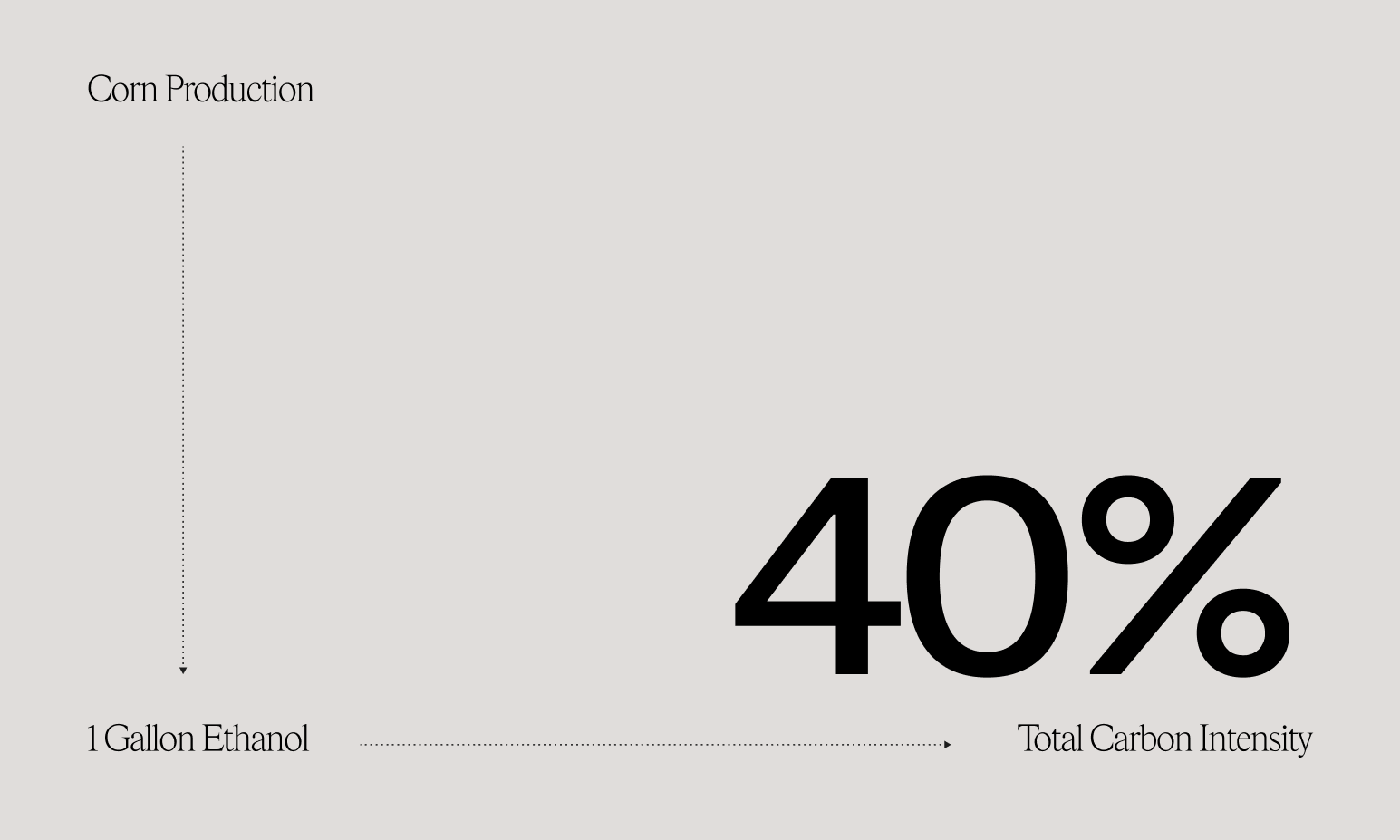

At other stages of the supply chain, carbon emissions are counted from the energy that biorefineries use to operate. Transporting the corn to the refiner and then distributing the product also releases a certain amount of carbon into the atmosphere.

Then you also have to consider other components of the life cycle. When corn is growing, it absorbs carbon from the atmosphere. Sometimes farm machinery will operate with biofuel and there are credits farmers can receive for producing an animal feed co-product.

It is a complicated equation. How do you measure how much carbon is sequestered in the soil? What amount of carbon is emitted from the energy used by trucks to transport the product? Or what about the emissions from fuel blenders or retailers? What interventions can be taken to reduce overall carbon intensity?

Increasing Accuracy and Lowering Carbon Intensity

It is essential to understand the emissions data at each part of the process with the highest degree of accuracy. Through NZero’s platform, processors have the ability not only capture the cleanest data but get recommendations on low-carbon interventions and easily report emissions to stakeholders.

The supply chain is relatively simple which means processors are able to isolate emission points within the life cycle. A single management change, capital investment, or operational adjustment can see the total carbon intensity dramatically drop.

For example, a farmer’s decision to introduce a no-till technique can increase carbon sequestration in the soil and see a 15% reduction in emissions at this stage. Farmers who introduce smart agricultural management practices can decrease the carbon intensity attributed to corn production down to a single digit. Potentially, even zero depending on land use practices.

Introducing solutions like carbon capture and storage (CSS) along with other practices can reduce carbon emissions, too. Ethanol industry trade groups, like the Renewable Fuels Association, emphasize that CSS is one of the most effective actions that processors can take to decarbonize. The group recommends that 90% of ethanol plants implement the technology by 2050. Dozens of Midwest ethanol plants support pipelines that would transport captured carbon from their facilities to underground storage, according to Reuters. Given the investment in this technology already, it becomes imperative to communicate the data tied to those reductions.

Interventions like CSS and other management practices could nearly cut the life cycle emissions of a biofuel in half. So it’s essential for a biofuel processor to be able to trace how those emissions reductions impact a gallon of their fuel.

NZero: A Partner in Sustainability Success

NZero can capture all of the necessary data and turn it into an actionable roadmap. The platform automates carbon emissions data by the hour and can bring an entire supply chain seamlessly into view. This means processors can calculate carbon intensity at every point of production and translate that data into decisions about carbon reduction strategies.

In our work we’ve seen how a reliable baseline measurement of carbon emissions provides processors with a strong foundation for any decision moving forward. NZero easily analyzes historical trends and offers insights into future scenarios to help processors reduce emissions. The platform has shown how to increase in production while also decreasing carbon intensity.

NZero can get to a level of granularity that is 35% more accurate than competitors. Processors can visualize the carbon intensity of feed stocks they are sourcing from individual farming operations and differentiate how climate-smart management practices can cut Scope 3 emissions.

All of this data ultimately leads to streamlined decision-making where processors can drastically reduce the carbon footprint of their final products. For those looking to maximize the benefits of better agricultural management practices, automate processes like CI scoring, and implement the right low-carbon infrastructure investments—NZero is your partner to unlock these sustainable solutions.